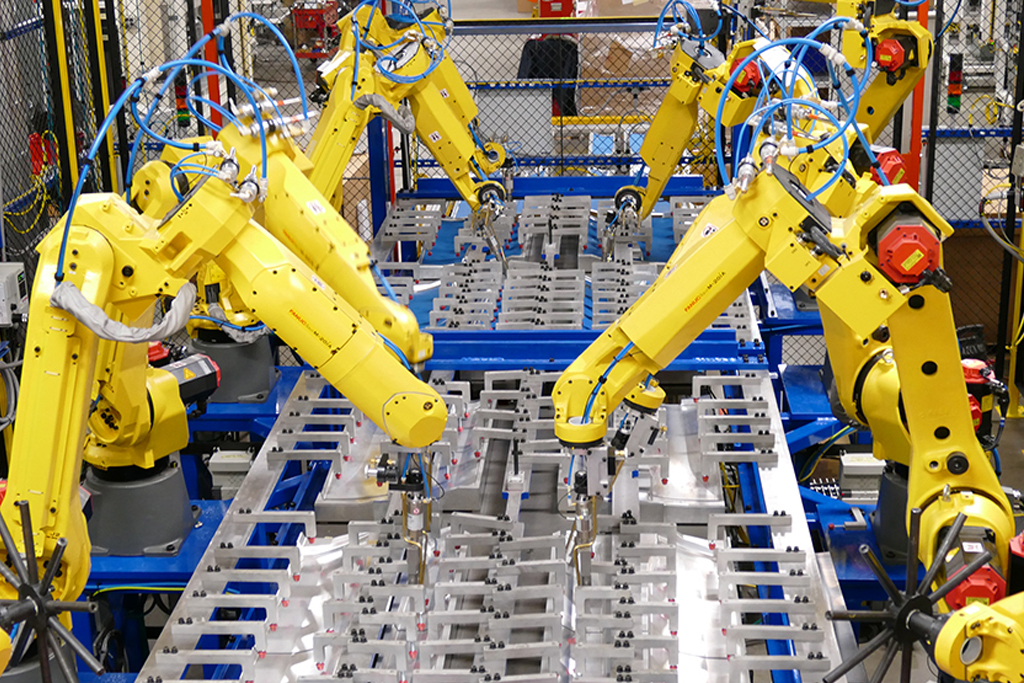

Automatic assembly.

Automated assembly is a key process in modern industrial manufacturing that involves the use of robotics and other advanced technologies to efficiently and accurately assemble parts and products. Automated assembly systems can handle a wide range of tasks, including material handling, part feeding, fastening, inspection, and testing. These systems are designed to operate with high speed, precision, and consistency, leading to improved quality and reduced production costs. One important aspect of automated assembly is the ability to integrate various machines and components into a single, cohesive system. This integration helps to streamline the production process and reduce the need for human intervention, resulting in increased efficiency and productivity. Overall, automated assembly has become a critical part of modern industrial manufacturing, helping companies to improve their production processes and stay competitive in a rapidly changing marketplace.