Automatic CNC.

To achieve higher efficiency and parts performance for low volume needs, we suggest using our CNC machining services. Whether it’s a design from an individual or a company, we offer various materials and qualified CNC machines and mold workers to start your project. Our advanced equipment provides a range of CNC machining services, such as milling, turning, EDM, and surface grinding. With precision 3 and 4-axis CNC milling and CNX turning lathe centers, our skilled machinists can create milled and turned parts using a wide variety of plastic and metal materials. Additionally, our CNC milling capabilities complement our 3D metal printing service, making us a one-stop-shop for your advanced designs.

CAD Drawings, CAM Programming and 3D printing

Utlilizing SoldWords 3D software, we are able to open and review just about any CAD drawings or solid part file. We also can create 3D part files from 2D drawings, Assembly parts and mechanism. With GibbsCAM software we have capabilites to program from 2D prints or import 3D solids. Using ABS or PLa materials we can create 3D modles. We use 3D printing to verify design and assembly concepts and for small assebly fixtures.

Machines

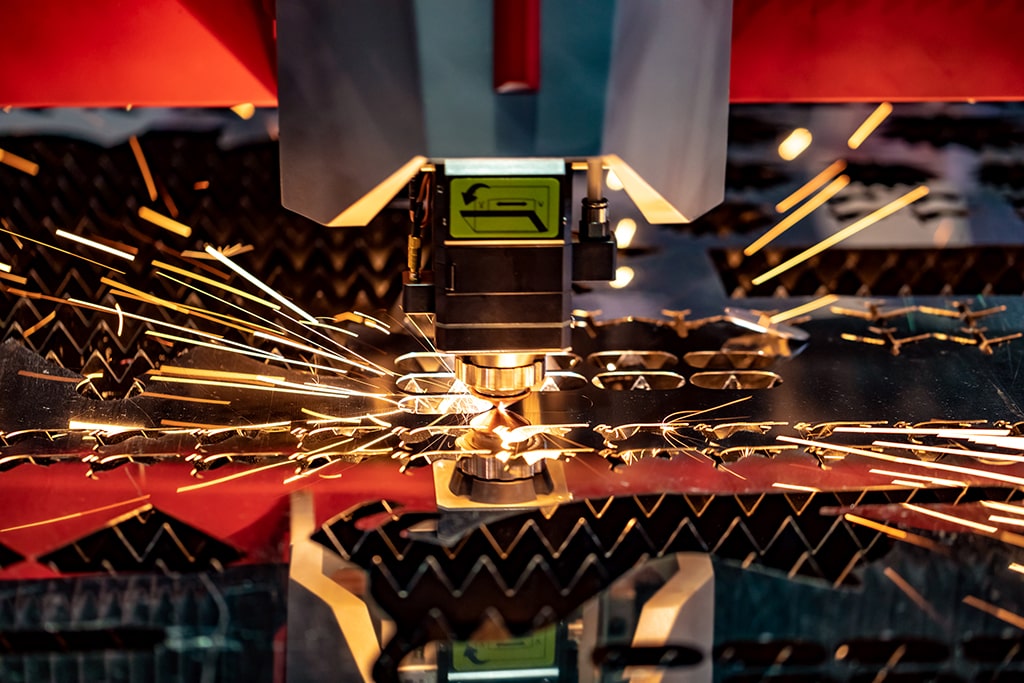

Bystronic laser cutting

Bystronic laser cutting

GYC Laser Machine

GYC Laser Machine

Mitsubishi RX-F

Mitsubishi RX-F

CNC MILLING

We offers a range of CNC Milling processes to produce

precise and complex parts with high-dimensional tolerances.:

• Carving Machine

• CNC Three-Axis

• CNC Four-Axis

• CNC Five-Axis

• Milling Machine/End Milling

• Gantry Milling

• Precision wet/dry flat laser cutting,

• Dry or wet laser cutting (to reduce thermal influence on the HAZ of the cut area).

Materials

Aluminium

is a highly ductile metal, making it easy to machine. The material has a good strength to weight ratio and is available in many types for a range of applications Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Brass/Bronze

has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity and has a golden (brass) appearance.

Copper

displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Plastics

ABS, Acrylic, Nylon 6/6, Polycarbonate, Polypropylene, G-10 Garolite, PEEK, PTFE

Steel

Alloy Steel, ASTM A36, Stainless Steel, Steel 1018

Titanium

Titanium Grade 2, itanium 6Al-4V

Finishes

Anodizing

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc.

Bead blasting

Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments.

Powder Coating

Powder coating forms a durable, wear resistant and corrosion resistant layer on the surface of parts. Powder coating can be used to apply colors to parts and is compatible with any metal

Surface Treatment

High polish, brush, sand blast, anodization, plating, lacquer paiting, silk screen, Pad printing and laser engraving.

Quality Control

Precision CMM (3D coordinate measuring machine), 2.5D projector; closed-loop QC system; Third party inspection avaliable is required;